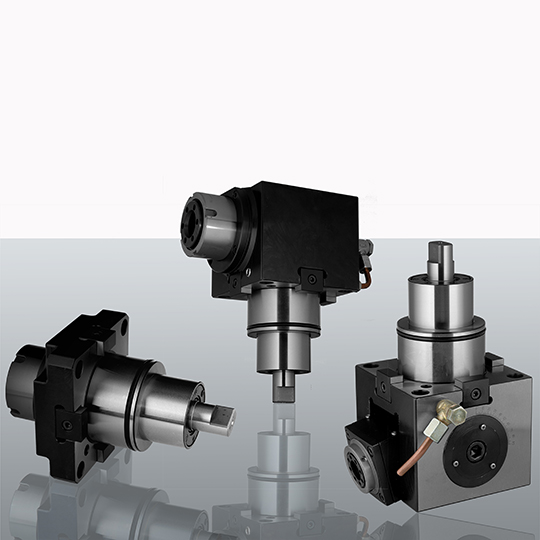

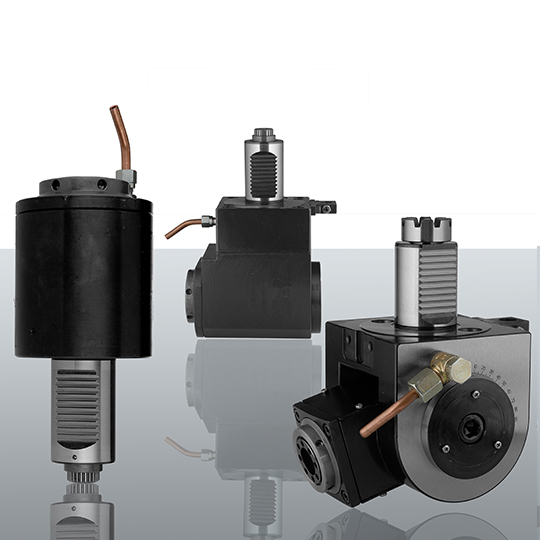

MOTORIZED TOOL HOLDERS

Solidity and precision guaranteed over time

The tool holders are mounted on numerically controlled turning machines equipped with a motorized tool post, and allow drilling, milling, and tapping operations to be performed, which would otherwise not be possible to execute, unless with a rest-machining operation of the pieced.

All our products are supplied with a certified quality control.

MAZAK

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

GOODWAY

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

BMT

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

VDI

VDI

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

TAKISAWA

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

OKUMA

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

MORISEIKI

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.

HAAS

Precision is a primary factor of our motorized tool holders, and this allows for a rotational capacity of our motorized modules equal to 0.01mm.

The quality of the Gleason gears coupled with very high precision bearings allow a tool rotation with a speed of 10,000 rpm. Certified quality control.